Engine mounts, though often overlooked, are essential components that play a critical role in your vehicle’s performance and comfort. These mounts secure the engine to the car’s chassis while minimizing vibrations and absorbing shocks. When engine mounts fail, they can lead to noticeable issues and even damage other parts of your vehicle. Here’s an in-depth look at what engine mounts do, how they work, and the signs they may need replacement.

What Do Engine Mounts Do?

Engine mounts serve three primary purposes:

- Securing the Engine:

- Engine mounts physically anchor the engine to the vehicle’s frame, ensuring it stays in place even during acceleration, braking, and cornering. Without properly functioning mounts, the engine could shift, causing misalignment and damage to surrounding components.

2. Dampening Vibrations:

- The engine generates significant vibrations and movement during operation. Engine mounts are designed with rubber or liquid-filled components to absorb and dampen these vibrations, providing a smoother and quieter driving experience. When mounts fail, vibrations increase, which can cause discomfort for passengers and put strain on surrounding parts, such as belts and hoses. Over time, this can lead to wear and tear on the engine itself.

3. Reducing Noise and Shock:

- Engine mounts isolate engine noise and prevent shocks from being transmitted to the vehicle’s cabin. This enhances driver comfort and protects the chassis from excessive stress. Damaged mounts can allow the engine to make contact with other components, leading to clunking or banging sounds that indicate internal impacts, which can compound into more severe issues if left unchecked.

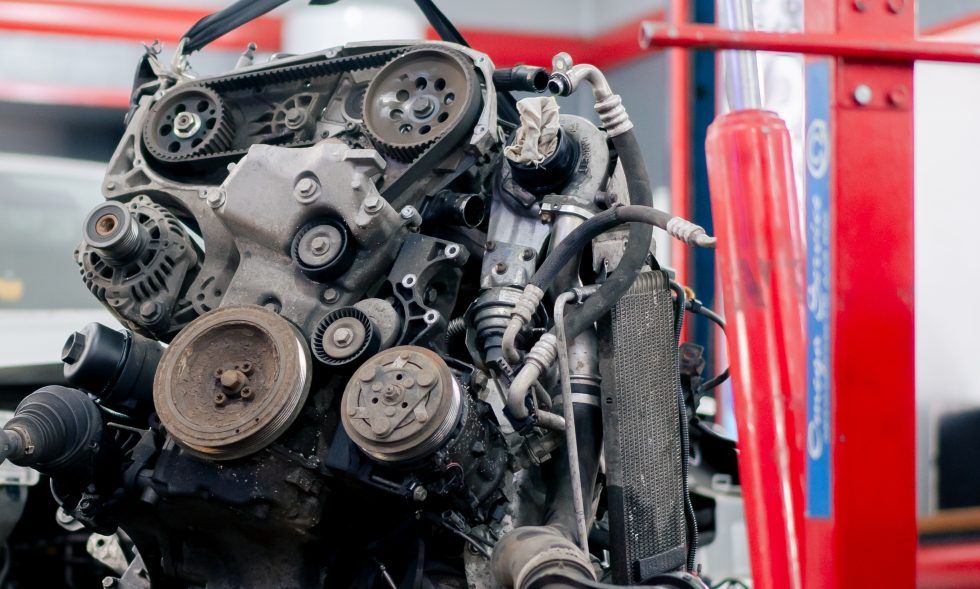

Types of Engine Mounts

There are several types of engine mounts, each with unique features:

- Rubber Mounts: The most common type, made of durable rubber to absorb vibrations and provide flexibility.

- Hydraulic Mounts: These contain a liquid-filled core to improve vibration dampening and reduce noise further.

- Electronic Mounts: Found in modern vehicles, these mounts adjust stiffness dynamically to optimize performance and comfort.

- Solid Mounts: Typically used in high-performance or racing vehicles, solid mounts offer maximum stability but transmit more vibrations to the cabin.

Signs of Failing Engine Mounts

- Excessive Vibrations:

- If you notice increased vibrations in the cabin, particularly during idling, it may indicate worn or damaged engine mounts. When mounts lose their dampening ability, the vibrations from the engine transfer directly to the vehicle’s frame.

2. Engine Movement or Clunking Sounds:

- A failing engine mount may allow the engine to move excessively, especially during acceleration or deceleration. This can result in clunking or banging noises as the engine shifts within its bay.

3. Unusual Engine Position:

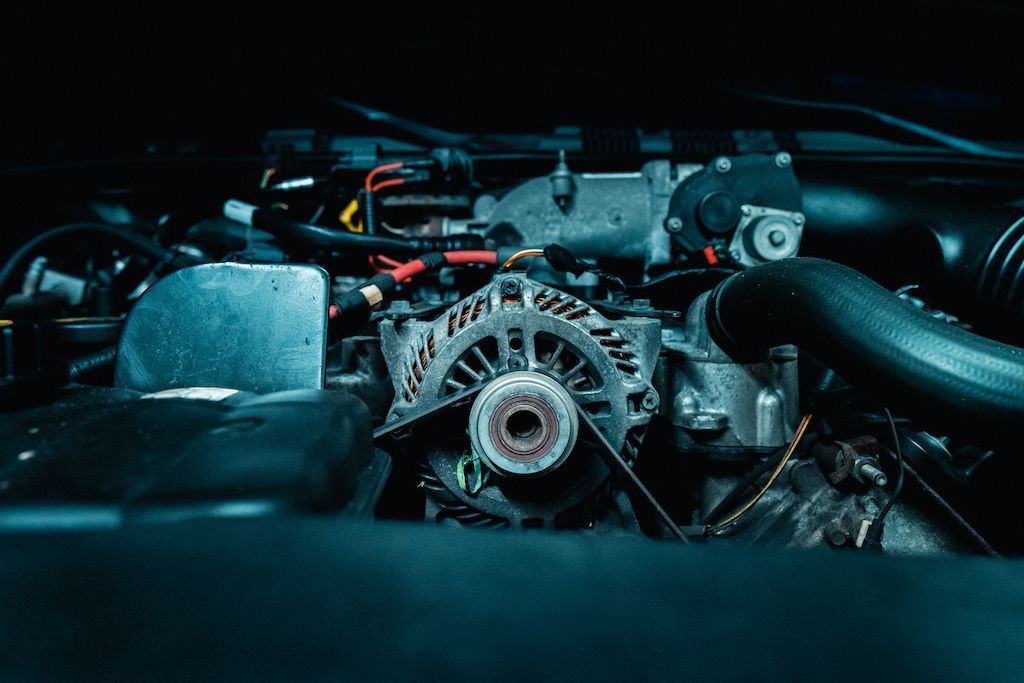

- Inspect the engine under the hood. If it appears tilted or misaligned, it’s a sign that one or more mounts may be broken or damaged.

4. Increased Noise:

- Worn engine mounts can fail to isolate engine noise, leading to a noticeable increase in sounds like rattling or knocking, particularly during gear changes or rough driving conditions.

5. Chassis Damage:

- If left unaddressed, failing engine mounts can cause stress on the chassis and other components, potentially leading to cracks or structural damage.

Causes of Engine Mount Failure

- Age and Wear: Over time, rubber components degrade due to heat, stress, and exposure to the elements.

- Oil Leaks: Leaking oil or other fluids can cause rubber mounts to deteriorate more quickly.

- Driving Conditions: Aggressive driving, frequent off-roading, or carrying heavy loads can place additional strain on engine mounts.

How to Inspect and Test Engine Mounts

- Visual Inspection:

- Look for cracks, tears, or signs of wear on the rubber parts of the mounts. Also, check for any signs of fluid leaks if you have hydraulic mounts.

2. Engine Movement Test:

- With the hood open, have someone start the car and lightly rev the engine while you observe. Excessive movement or shifting of the engine may indicate worn mounts.

3. Professional Diagnosis:

- A certified mechanic can perform a more detailed inspection and determine if your engine mounts need replacement.

Why It’s Important to Replace Failing Engine Mounts

Failing engine mounts can lead to a cascade of problems, including:

- Damage to the Engine, Transmission, or Chassis: When engine mounts fail, the engine can shift out of position, placing undue stress on nearby components. This can lead to misalignment, broken parts, or even cracks in the chassis. The resulting repairs can be costly and time-consuming.

- Increased Wear on Other Components: Loose or failing engine mounts can cause excessive vibrations, which may wear out belts, hoses, and other engine components faster than normal. This can shorten the lifespan of critical systems and result in frequent breakdowns.

- A Bumpier Ride: When engine mounts weaken, you may notice a jolt or thump during gear changes or when traveling at higher speeds. This occurs as the engine moves more than it should, leading to a less stable and smooth ride.

- Impact Noises: A damaged engine mount can produce clunks, bangs, or rattles as the engine moves and contacts other parts. These noises are not just distracting but can indicate that internal components are being damaged.

- Safety Risks: A failing mount can cause the engine to move unpredictably, potentially damaging steering, braking, or electrical systems. In severe cases, the engine may even detach from its mounting points, creating hazardous driving conditions for both the driver and others on the road.

What to Do If Your Engine Mounts Are Failing

If you suspect your engine mounts are failing, follow these steps:

- Visit an Auto Repair Shop:

- A professional mechanic can confirm the issue and recommend the appropriate solution. In most cases, replacing the damaged mounts is necessary.

2. Choose Quality Replacement Parts:

- Opt for high-quality mounts designed for your vehicle’s make and model to ensure durability and performance.

3. Inspect Related Components:

- During the repair, have your mechanic inspect other nearby components for damage caused by failing mounts.

Final Thoughts

Engine mounts may not be the most talked-about component of your vehicle, but their role is critical. Ignoring the signs of failing mounts can lead to costly repairs and safety risks. By staying proactive and addressing issues early, you can ensure a smoother, quieter ride and extend your vehicle’s lifespan.

At C&G Auto Center, we understand the importance of maintaining your vehicle’s performance and safety. Our ASE certified technicians are equipped to diagnose and repair any of your engine’s components. We only use high-quality replacement parts to ensure your car runs smoothly and reliably.

Contact Information:

- Phone: (407) 355-0638

- Address: 4155 W Oak Ridge Rd Orlando, Fl 32809

- Hours: Monday to Friday, 7:00 AM – 6:00 PM

If you’re experiencing symptoms of bad engine mounts, don’t wait. Contact C&G Auto Center today to schedule an inspection or repair. Call us at (407) 355-0638 or book an appointment online for expert service and peace of mind.